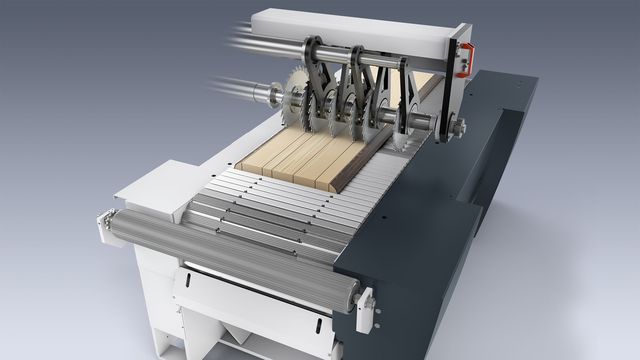

WEINIG ProfiRip KR 610: Optimal performance and intelligent technology

A powerhouse for the highest demands in modern production. Ideal in the performance range of up to 140 mm cut height. Extreme flexibility and optimal wood recovery with up to 6 adjustable saw blades. Optimal production performance with processing widths of 610 mm. With feed speeds of up to 80 m/min, the ProfiRip 610 represents optimal performance, flexibility and productivity.

Different requirements - different prices

The price of a WEINIG machine is just as individual as your requirements are. Therefore, let us discuss briefly what is most important to you – you will then receive our preliminary, non-binding quote.

Personal advice – for higher productivity and greater efficiency

Together with your WEINIG expert you will find the ideal machine for your requirements. Simply submit the completed form, and your local WEINIG expert will be happy to discuss all further details with you.

The WEINIG ProfiRip series provides

- High performance potential

- Maximum stability and productivity — even with extreme loads

- Glueable cut

- Outstanding user-friendliness

- SafetyPlus anti kick-back device

- Can be optimally integrated into system solutions

- Up to 6 movable saw blades

The WEINIG ProfiRip KR 610 provides

- Optimal cutting quality

- Up to 6 automatically adjustable saw blades

- Short setup times

- Large performance range

- Variable for a range of applications

- Robust, long-lasting construction

Technical Details

Double-sided prism guide

The double-sided prism guide of the feed chain is completely play-free. The accurate workpiece transport that this achieves is a prerequisite for precise cutting results. The specially harmonized alloys also guarantee a long service life of the feed system.

Moving blades: Unlimited flexibility

In terms of ripping, changing timber widths, qualities and defects mean average wood losses of 8% with a standard fixed arbor setup. The RaimannLine moving blade technology ensures efficient use of the raw material. With up to four movable saw blades, you can adapt your ProfiRip individually to any rough board.

Optimizing wood recovery in this way reduces your material and warehousing costs significantly. In other words, wood optimization means cost minimization.

The almost unlimited possible combinations of fixed and adjustable saw blades also decisively increase the flexibility of your production, thus enabling just-in-time and small batch production.

SafetyPlus

SafetyPlus provides optimal protection for the machine operator. An additional Kevlar curtain complements the conventional splinter curtain. This optimally seals the danger zone. This patented safety feature is standard with all WEINIG rip saws.

Options for extension

TimberMax 5.0: How optimizing is done today

The TimberMax 5.0 optimization program allows you to extract the most out of your raw materials.

ROTO chain brushes

The rotating chain brushes reliably clean residual resin and sawdust from the feed chain.

References

Further information

Brochures

Simple, fast and sustainable: more details in a downloadable PDF document.

ProfiRip series brochure (PDF, 4 MB)