Cross-cutting with WEINIG: for maximum material yield

Cross-cutting (length cutting) is one of the first most important steps in solid wood processing. Manual cutting is a laborious job and carries a high risk of accidents. Both of these are avoided using modern cutting techniques.

WEINIG has experience from building thousands of automatic optimizing cross-cut saw and so has unique skills, offering a wider range of products than any other manufacturer. Irrespective of whether it is undertable cross-cut saws, optimizing cut-off saws (with and without position slider) or optimizing cross cut systems. The objective is always the maximum material yield for you.

Optimized cross-cutting with WEINIG

- Cutting out errors

- Sawing fixed lengths

- Cutting packages to length

- Optimizing board material

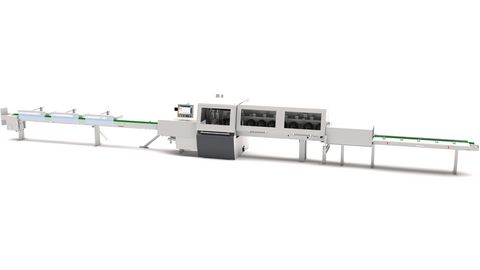

WEINIG products and solutions for cross-cutting

WEINIG can offer you machines in all performance classes with different specifications in the area of cross-cutting. Intelligent system solutions, optimization software and automations complete the range of products.

WEINIG SOLID CUT U 500

Future-oriented manual cross-cutting – safe and efficient

WEINIG SOLID CUT TF 1500

Built for automatic cross-cutting - come what may.

Detail page SOLID CUT TF 1500WEINIG SOLID CUT TF 2000 series

Strong concept for profitable, high-performance cross-cutting

Detail page SOLID CUT TF 2000 seriesWEINIG SOLID CUT TF 5000 series

Optimizing cross-cut saws – built for maximum dynamism and performance with every cut.

Detail page SOLID CUT TF 5000 seriesWEINIG SOLID CUT PF 900 series