WEINIG tools: Conventional, hydro or PowerLock?

We offer the right WEINIG cutter head for every desired surface and feed speed: as a tool with conventional clamping, as a classic tool with hydro-clamping or as a modern PowerLock tool. We are always guided by your precise wishes and requirements.

Downloads

Only the outcome matters: potential to improve performance

Concentric tolerance, spindle speed and the number of knives in the cutter head determine the surface quality of the work piece. The cutting circle of the individual knives must be exactly the same so that all knives are cutting. The WEINIG tool system offers the technical solutions on this issue down to thousandths of a millimeter.

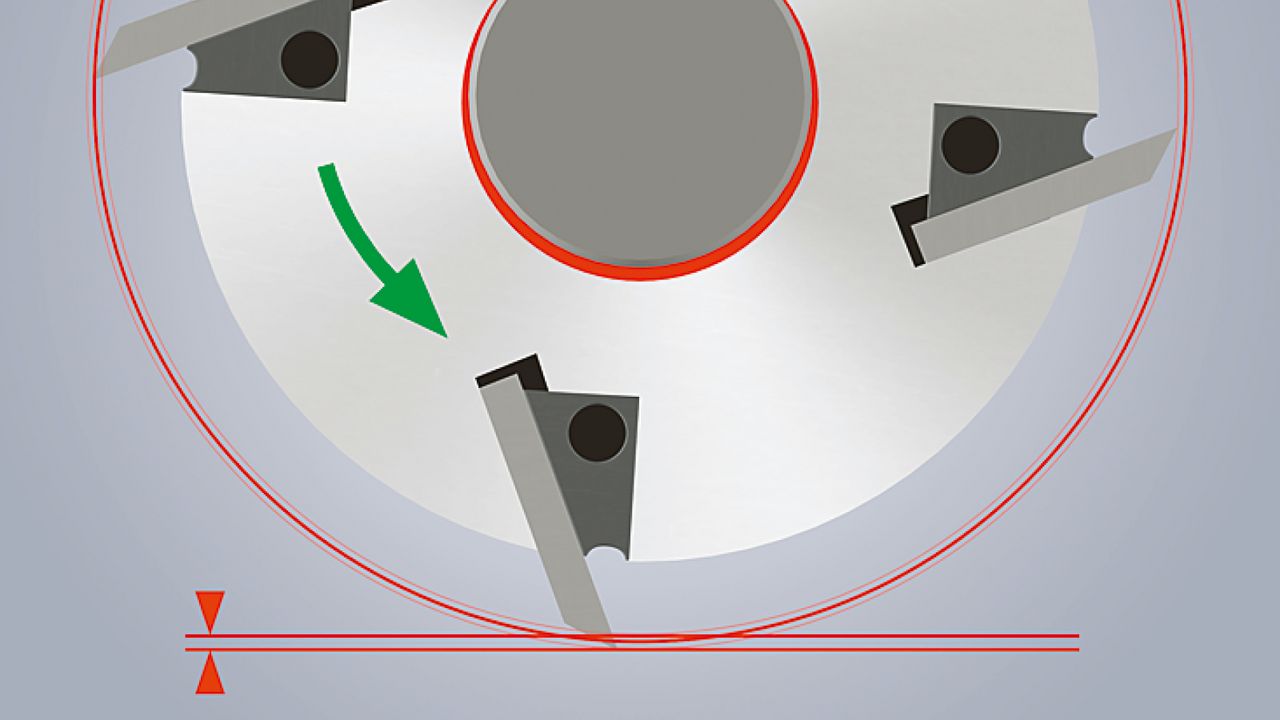

Conventional tools

The specified tolerances of the tool bore and the milling spindle result in a difference of 0.05 mm in the cutting circle of the individual knives.

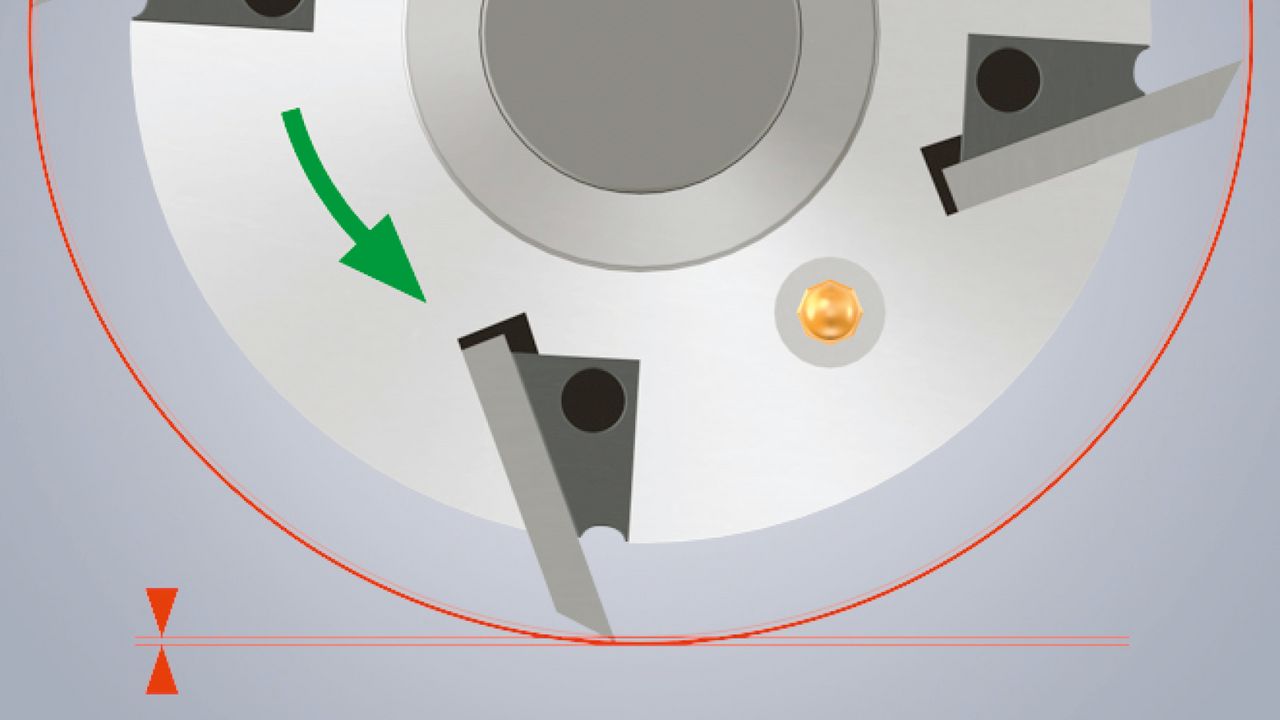

Hydro-tools

Thanks to the centric clamping tension of the hydro-tool, there is a deviation of just 0.005 mm in the cutting circle of the individual knives. However, even this minimum tolerance means that only one cutting edge is responsible for the surface quality of the work piece.

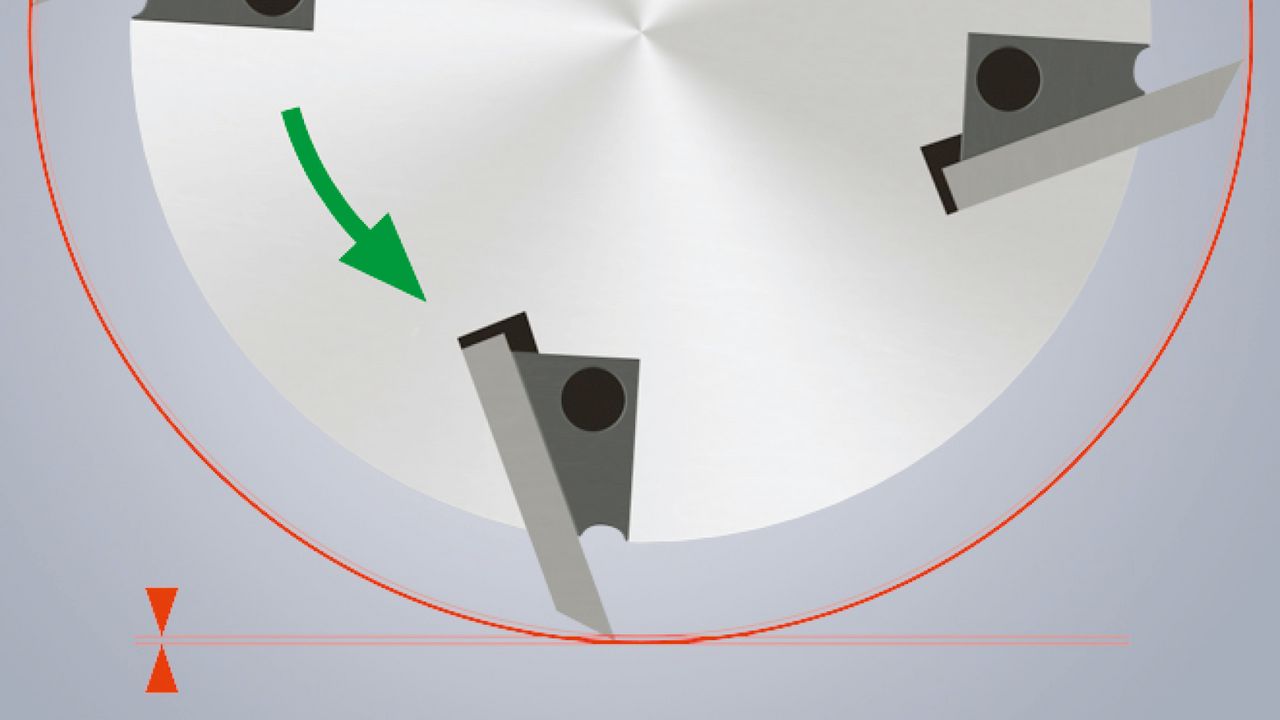

PowerLock

Thanks to the PowerLock's centric clamping, there is a deviation of just 0.003 mm in the cutting circle of the individual knives. However, even this minimum tolerance means that only one cutting edge is responsible for the surface quality of the work piece.

In order to ensure that all cutting edges in the tool body have a fully uniform cutting circle and are thus all used equally frequently, the tool must be jointed in the moulder . The cutting edges are sharpened with a joint stone when the tool is rotating at its operating speed. This process removes all other tolerances in the tool cutting circle.