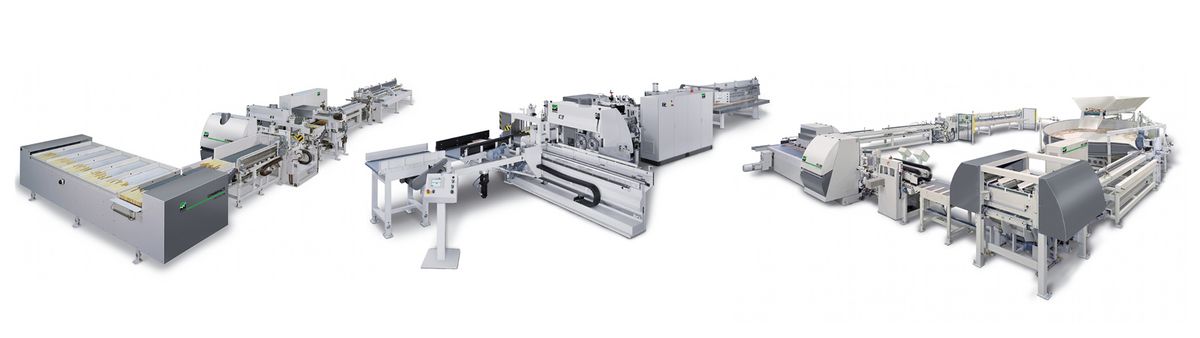

WEINIG Short timber finger jointing lines: Unrivaled in all performance classes as a result of the modular system

The flexible modular design allows machines to be set up according to your individual requirements.

The use of specific modules means that both standard and customer-specific solutions can be found – for both finger jointing lines with wood entry lengths below 1,000 mm and for finger jointing lines with wood entry lengths above 1,000 mm.

The principle can be used for all performance classes: From the SOLID JOINT PS 2000 entry model to the Ultra, CombiPact and Turbo-S models up to the high-performance class with the HS120 and HS200 horizontal finger jointing lines. All in all, lines for the highest quality standards in all performance classes, the commercial production of, for example: Solid wood panels or window scantlings.

Invest in a finger jointing line and use your residue wood to produce a valuable, high-quality product.

• Top quality jointing

• Very short setup times

• Fast, simple setup

Can be retrofitted to optimize performance and enable automation.

All machines

WEINIG SOLID JOINT PS 2000

Enormous performance potential for those starting out

- Incredibly easy to operate

- Compact option

- Shortest depreciation time

- For vertical and horizontal finger joints

- For 4 mm, 10/11 mm and 15/16.5 mm finger joint lengths

WEINIG SOLID JOINT PS 2500 / SOLID JOINT PS 3500

SOLID JOINT PS 2500 finger jointing line — the powerful mid-level option

- Frequency or servo-controlled shaper table feed

- Infeed length up to 1,000 mm (optional also up to 1,500 mm)

- Semiautomatic to fully automatic system configuration possible

- Shaper heights up to 205 mm (optional also 225 mm)

- Performance doubling from Ultra to Ultra TT

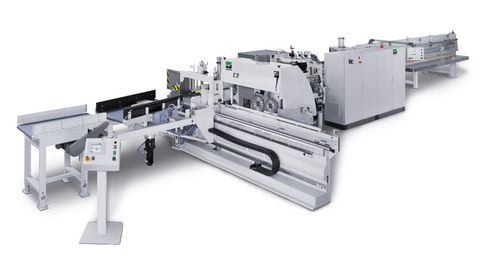

WEINIG SOLID JOINT PD 5500

The flexible line for vertical and horizontal profiles

- Frequency regulated shaper table feed

- Fully automatic system for the higher performance area

- Shaper combination in very compact construction form

- Universal system for all types of finger joint

- Almost all types of glue can be used

WEINIG SOLID JOINT PD 8000

The whole package for the highest performance and demands

- Servo drive for the shaper table feed

- Fully automatic system for the higher performance area

- Shaper combination with many buffer places for highest performance

- Universal system for all types of finger joint

- Almost all types of glue can be used

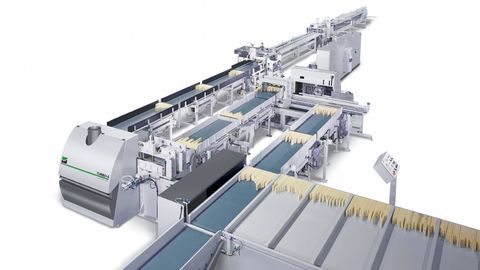

WEINIG SOLID JOINT HS 1200 / SOLID JOINT HS 2000

The nonplus ultra of the high-performance class

- From a manual to a fully automatic system

- Heavy cast iron construction of the shaper body

- Shortest wood entry length 110 mm

- (Wood) quality monitoring, defective parts are automatically identified and removed

- Glue monitoring using a scanner (optional)

WEINIG finger jointing line for short timber pieces offers you

- Finger joint profiles for all areas of use

- Maximum precision and stability of finger joints

- Robust and powerful

- High operational capacity, up to 200 pieces/min (28 km/8h-shiftr)

- Convenient and user-friendly

- Processing with one and two component glue

- Compact and efficient production process

- Statistics and production data recording

- Customized level of automation - from manual to fully automatic

- Expandable using peripheries, such as feeding systems and stacking systems