WEINIG EasyScan: The most profitable solution for wood optimization

Of all the process stages in solid wood processing, cutting offers the greater potential for optimization. No wonder that many companies start here to improve the performance of their production lines. The use of scanner technology also provides a key function. Defect detection via camera and laser is an ultra-efficient instrument in the race for maximum productivity, optimal quality and the shortest delivery times. Speed and accuracy are among the scanner's main attributes.

The results are improved value creation, consistently high product quality and increased profits. Consequently, in large modern companies, the scanner has long been an integral component of the cutting system and has replaced manual workpiece inspection. Smaller companies, on the other hand, often struggle with making the leap into the digital age of production. They have particular reservations in terms of cost-effectiveness. Now the new Weinig EasyScan has arrived to allay all remaining concerns.

Different requirements - different prices

The price of a WEINIG machine is just as individual as your requirements are. Therefore, let us discuss briefly what is most important to you – you will then receive our preliminary, non-binding quote.

Personal advice – for higher productivity and greater efficiency

Together with your WEINIG expert you will find the ideal machine for your requirements. Simply submit the completed form, and your local WEINIG expert will be happy to discuss all further details with you.

This offers you the WEINIG EasyScan C

- Increased recovery since the detection accuracy of the scanner is far superior to manual marking

- Reduced labor costs, since labor-intensive manual marking is dispensed with

- More flexible production since many different qualities and products can be produced at the same time

- High productivity thanks to automated defect detection

Technical Details

Cross-cutting optimization explained simply

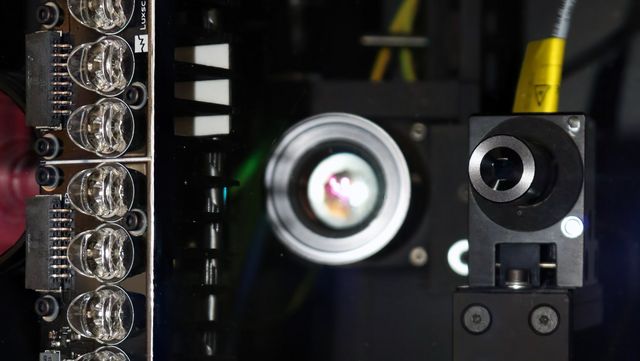

Step 1: LuxscanLine scanners are based upon various sensors, such as laser and color cameras or X-ray. Your WEINIG expert will define the right sensors and the best combination of these, harmonized with wood types, surface properties and customer requirements. Our objective is to achieve the best possible quality of information for the required application.

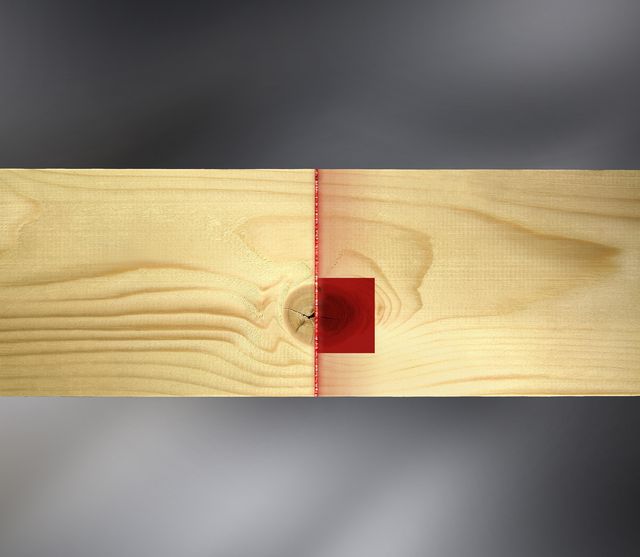

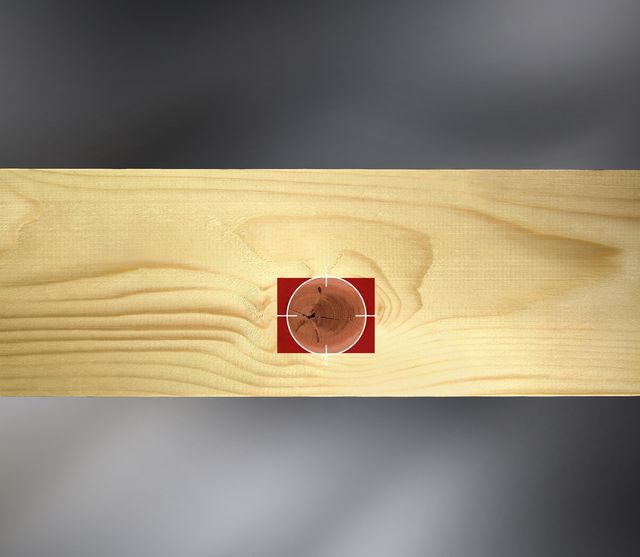

Step 2: Image processing is handled by the highly sophisticated OptiCore software. This detects and identifies defects as well as color deviations on the board. The ideally adapted sensor data ensures optimal data processing and defect detection.

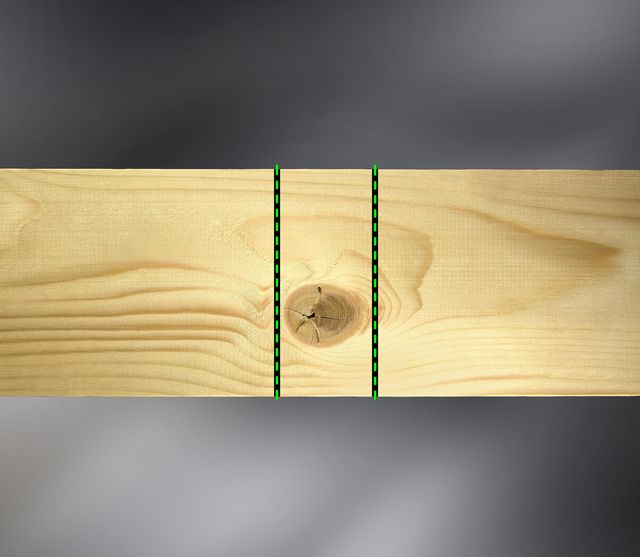

Step 3: Optimization via the high-performance OptiCore software calculates the best solution during cross-cutting. In doing so, it takes into account the various customer requests and requirements. Based upon the precise board data calculated during image processing, the board is optimized in accordance with customer requirements. This allows a virtually unlimited number of qualities and products to be defined. Thus, even complex products can be ideally optimized. This allows the creation of almost any type of end product.

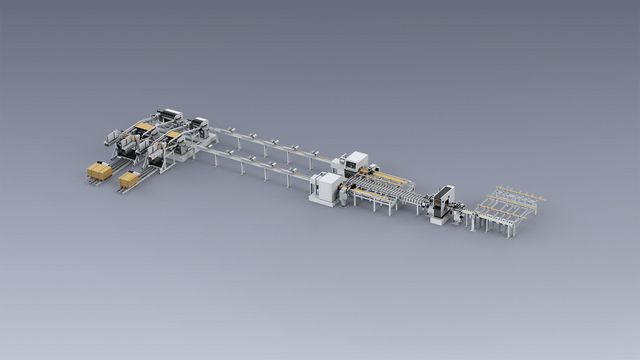

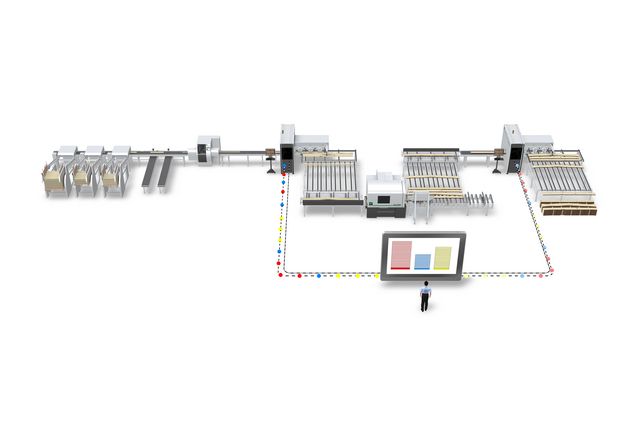

EasyScan+ C layout suggestions

The sensors: The key to success

All sensors are ideally protected by a dust-proof housing.Our laser cameras are installed in every system as standard. With the fastest speed available on the market, these guarantee a high resolution and optimal results. Performance is continually improving through continuous development of this industrial sensor system. This technology detects defects such as knots, pith, cracks, etc. A sophisticated laser system also reliably detects 3D surface defects, such as holes and wane.

In addition, optional color modules improve the scanner's detection. Color defects, as well as cracks and insect holes, are detected more reliably than ever before.

OptiCore AI : Revolution in der Fehlererkennung

OptiCore AI ist eine intelligente Bildverarbeitungssoftware, die Deep Learning, eine Klasse von neuronalen Netzwerken aus dem Bereich der künstlichen Intelligenz, für die Erkennung der Holzmerkmale verwendet.

Diese revolutionäre Methode kann die Erkennungsgenauigkeit erheblich verbessern, da die Software lernt, Bilder wie ein menschliches Gehirn zu verarbeiten. Mit OptiCore AI kann der Scanner trainiert werden, Holzdefekte nach vordefinierten Parametern automatisch zu analysieren und zu erkennen. Die Erkennungsergebnisse und ihre Wiederholbarkeit werden so deutlich verbessert und die Einstellzeit verringert.

Options for extension

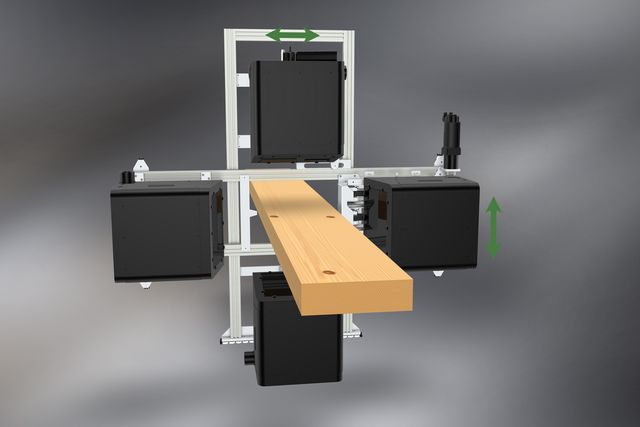

Automatic camera positioning and processing of decreasing widths

The automatic camera positioning moves all cameras into the ideal position, thus guaranteeing optimal picture quality and resolution. It also prevents operator error, thus reducing production losses to a minimum.

OptiLink: Ideal optimization via connected processes.

Using complex production processes has always been a difficult task. Linking various applications and production lines complicates the flow of information.

Further information

Brochures

Simple, fast and sustainable: more details in a downloadable PDF document.

EasyScan brochure (PDF, 1 MB)