CombiScan Sense C: THE scanner for optimizing your cross-cutting

The CombiScan Sense C is specially equipped for cross-cutting applications. It can be upgraded with one of many options for all requirements, offering optimal flexibility. Based on the cutting-edge technology used , it can improve your production decisively.

The scanner is invested with all of WEINIG's experience in cross-cutting optimization in a single package. The variable software and hardware options of the scanner represent leading-edge technology.

Simple optimization is the key to efficient production. The high-performance optimization allows a variety of qualities and zones to be created and combined into end products. Products and qualities are stored in the database and can be selected at any time via drag and drop. The logical user guidance of the scanner simplifies settings and can, therefore, be easily used by all personnel.

With its various sensor options, the scanner can be adapted to customer requirements, guaranteeing ideal results every time. Whether hardwood or softwood, window scantlings or glulam, beads or panels, furniture production or cladding boards, this scanner allows you to achieve optimal results every time.

Different requirements - different prices

The price of a WEINIG machine is just as individual as your requirements are. Therefore, let us discuss briefly what is most important to you – you will then receive our preliminary, non-binding quote.

Personal advice – for higher productivity and greater efficiency

Together with your WEINIG expert you will find the ideal machine for your requirements. Simply submit the completed form, and your local WEINIG expert will be happy to discuss all further details with you.

The WEINIG CombiScan Sense series provides

- Fast return on investment

- Optimization of your products by value, utilization or production objective

- Extensive statistical functions in real time

- Compatible with all high-performance optimizing cross-cut saws, high-performance rip saws and sorting systems

- Optional processing of boards with decreasing widths in one assignment

- Surface scanning with laser and color cameras.

- Optionally upgradable sensor concepts (X-ray technology, humidity and shape measurement and much more)

- Complete defect detection: Unprocessed edges, branches, tears, pith, resin pockets, blue/red rot...

- Tested industrial sensor technology

The WEINIG CombiScan Sense C provides

- Increased recovery since the detection accuracy of the scanner is far superior to manual marking

- Reduced labor costs, since labor-intensive manual marking is eliminated

- Maximum productivity thanks to automated defect detection and optimization

- More flexible production since many different qualities and products can be produced at the same time

- Ability to control the quality of end products according to individual customers, etc.

- Increased quality of end products

Technical Details

Cross-cutting optimization explained simply

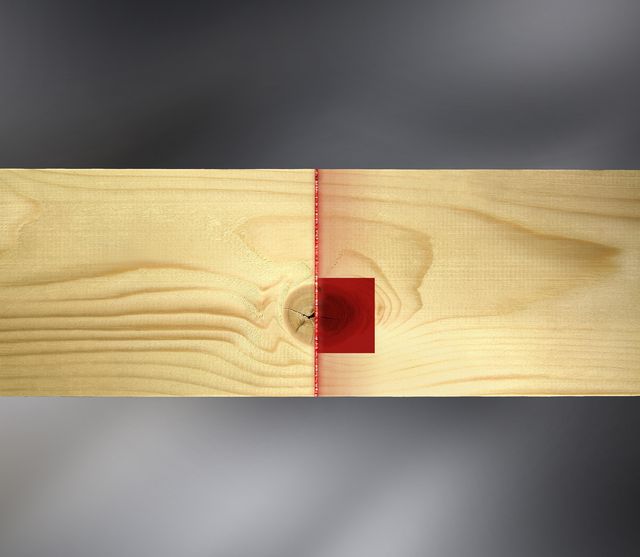

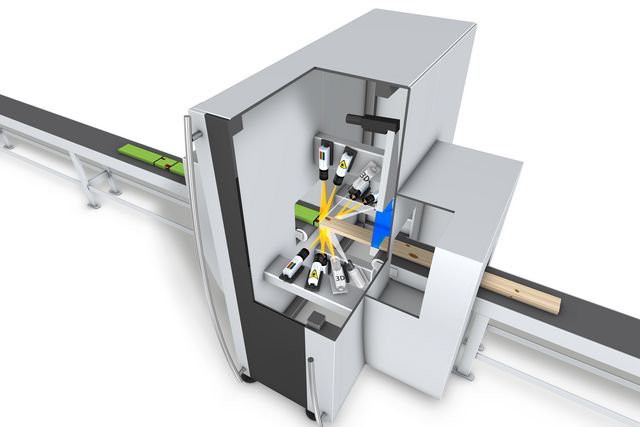

Step 1: LuxscanLine scanners are based upon various sensors, such as laser and color cameras or X-ray. Your WEINIG expert will define the right sensors and the best combination of these, harmonized with wood types, surface properties and customer requirements. Our objective is to achieve the best possible quality of information for the required application.

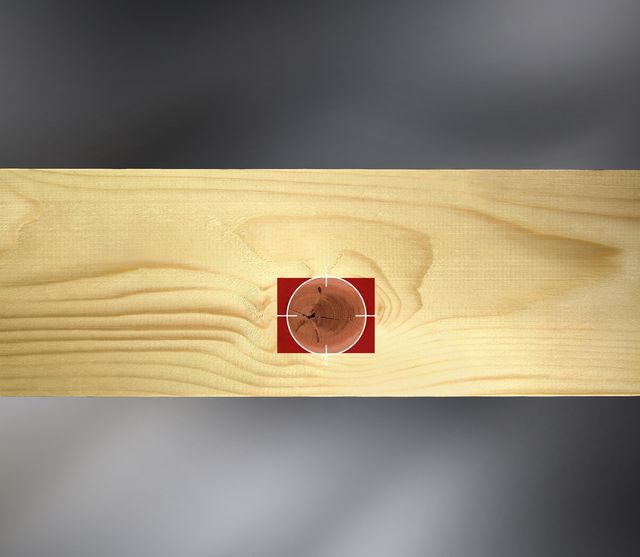

Step 2: Image processing is handled by the highly sophisticated OptiCore software. This detects and identifies defects as well as color deviations on the board. The ideally adapted sensor data ensures optimal data processing and defect detection.

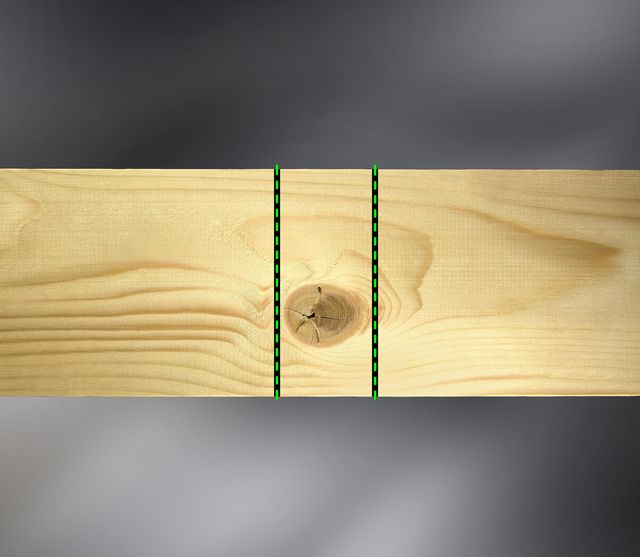

Step 3: Optimization via the high-performance OptiCore software calculates the best solution during cross-cutting. In doing so, it takes into account the various customer requests and requirements. Based upon the precise board data calculated during image processing, the board is optimized in accordance with customer requirements. This allows a virtually unlimited number of qualities and products to be defined. Thus, even complex products can be ideally optimized. This allows the creation of almost any type of end product.

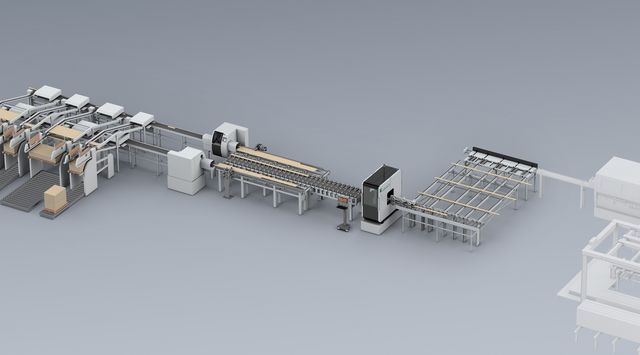

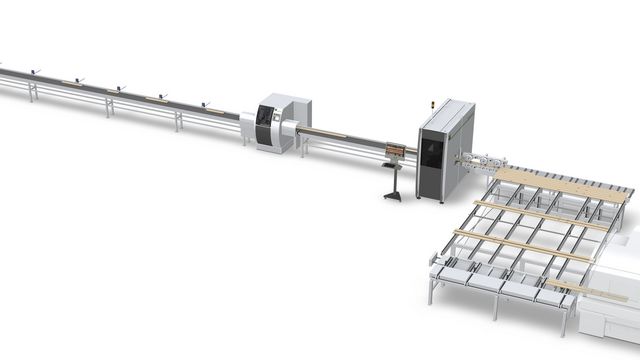

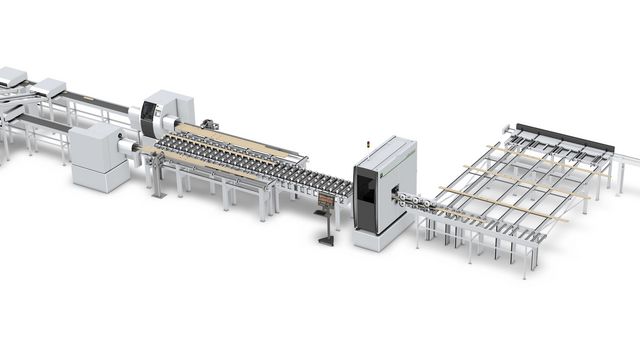

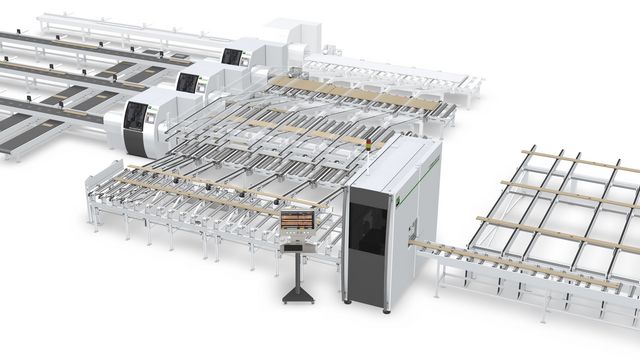

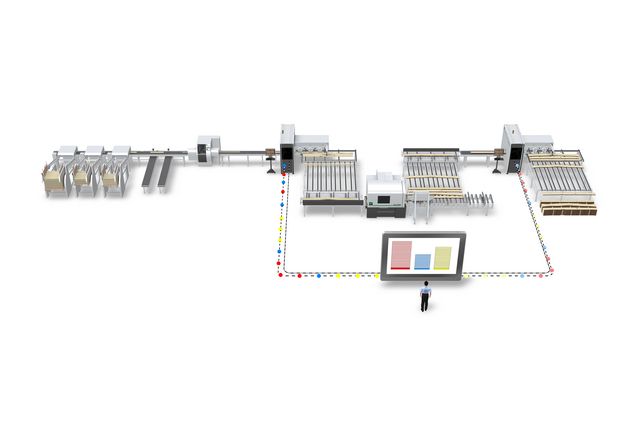

CombiScan Evo C layout suggestions

The CombiScan Evo C is suitable for one or several cross-cut saws.

The sensors: The key to success

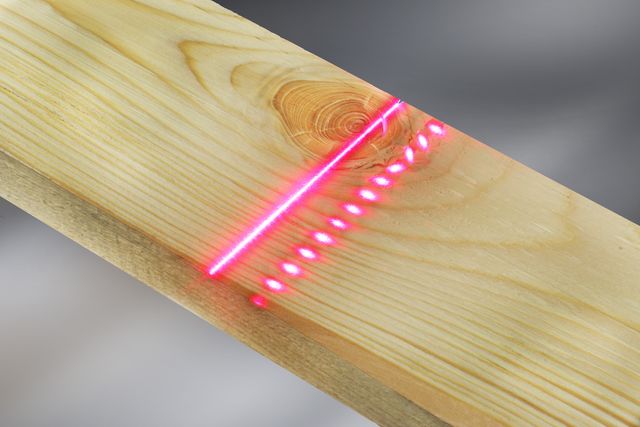

All sensors are ideally protected by a dust-proof housing. Our laser cameras are installed in every system as standard sensors. With the fastest speed available on the market, these guarantee a high resolution and optimal results. Performance is continually improved via constant evolution of this industrial sensor system. This technology detects defects such as branches, pith, cracks, etc. A sophisticated laser system also reliably detects 3D surface defects, such as holes and rough edges of the wood.

In addition, color cameras improve the scanner's detection as standard. Higher resolutions, both in the longitudinal and transverse direction, detect color defects as well as cracks and insect holes more reliably than ever before. Different versions of the color camera ensure the ideal scanner performance for every application.

OptiCore: The new benchmark in the world of automated optimization

Beside the sensors, such as laser and color cameras, X-ray, curvature measurement, etc. the software plays the largest role in cross-cutting optimization. Simple operation, convenience and confident decision-making are essential in this area.

The system should be easy to understand, intuitive to operate and reliable in terms of availability and performance. OptiCore software fulfills all of these criteria. With its visual and operational design, inspired by the OptiCom Direct software from DIMTER, operation of both machines is almost identical. OptiCore also offers the trusted optimization structure that allows you to structure your production as quickly and easily as it allows you to produce.

OptiCore is able to process an unlimited number of products and qualities. By specifying qualities in terms of zones, it both increases recovery and enables the customer to achieve greater product diversification. Highly precise specification of qualities allows more specific products to be produced. Combined with the high degree of accuracy in the measurement of wood features, this means your raw material is used significantly more efficiently. The various optimization modes – optimization by value, recovery or production objective – make the scanner technology even more interesting. These allow you, for example, to set production objectives, which are subsequently processed. Processing orders with parts lists is now no longer a problem. The commonly used software interface also creates synergies in the controls of the machines. For example, fill level information for the OptiCut stacker can also be taken into account in the optimization. This is just one additional example of current WEINIG leading-edge technology. That way, you are equipped to deal with the requirements and challenges of the future at all times.

OptiLink: Ideal optimization via connected processes.

Using complex production processes has always been a difficult task. Linking various applications and production lines complicates the flow of information. OptiLink was developed to optimize production management by centralizing the information. With a single access point to all information, just-in-time production is no longer a complex challenge. OptiLink decreases operator errors and reduces the inventory of semi-finished goods. A further benefit is the quick and simple data management with regard to ERP systems. This even allows production of single-item batches thanks to sophisticated statistical functions. Although OptiLink was originally developed purely for linking cross-cut scanners and rip scanners, it is now possible to connect many other cutting-related machines.

Options for extension

Fiber analysis: Maximum cutting accuracy

An essential component of optimizing recovery and value creation is a precise cutting position, particularly with finger jointed products. The "dual scatter" system, comprising a line laser and a dot laser, enables this precision.

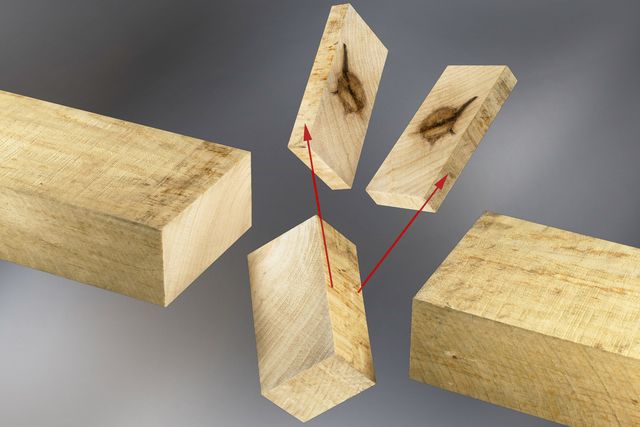

ACM angled crack detection: Optimize your crack detection

Detecting angled, non-vertical cracks has always been subject to limitations owing to the positioning of the lasers. Thanks to the use of 4 specially positioned lasers, the Angle Cracks Module (ACM) is able to provide decisive additional information.

X-ray sensor: Enhanced defect detection

X-ray sensors can not only be useful for rough-sawn or dirty surfaces, but also for wood types with wide color variations. Their primary benefit is that localized internal defects are detected via changes in density.

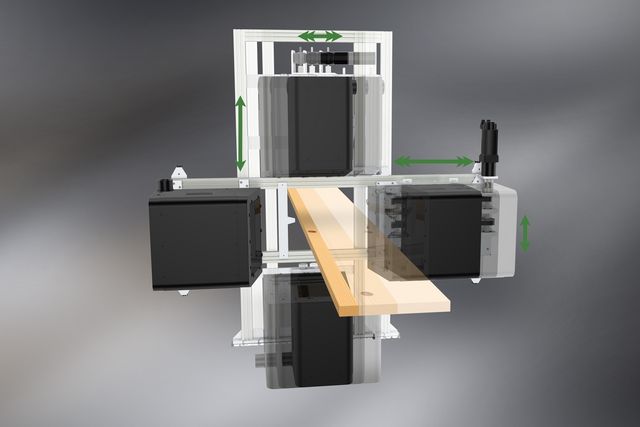

Automatic camera positioning and processing of decreasing widths

The automatic camera positioning moves all cameras into the ideal position, thus guaranteeing optimal picture quality and resolution. It also prevents operator error, thus reducing production losses to a minimum.

ShapeScan: Reliable detection of curvature and warping

The ShapeScan is the ideal option when it comes to detecting a particular curvature and warping as a defect. The cupping can also be optionally measured. The ShapeScan T can calculate the curvature or warping via sensors in the cross conveyor.

Front-end scanner: Quality control the easy way

The front-end scanner is installed behind a cross-cut saw. It scans the cut parts from both sides. This allows defects inside the boards, such as pith, to be detected via their contrast. This information is used for subsequent sorting of products for finger jointing or shared profiles and forwarding of these to a new ejector.

Marking station: Marking of cuts and grades

A marking station is the ideal solution for connecting a scanner to one or more existing cross-cut saws if the operator wants to avoid complex mechanization or direct data connection is not possible. Cuts, qualities and twisting is imprinted on each board so that these are forwarded to the saw free from defects.

Sorting by strength: The ideal option for construction timber

Sorting by density or strength is becoming increasingly important. Information about density and strength can be measured via X-ray and/or fiber analysis or imported from external devices, such as the EScan and used during optimization.

OptiLink: Ideal optimization via connected processes.

Using complex production processes has always been a difficult task. Linking various applications and production lines complicates the flow of information.

Areas of application

Glulam

Planing glulam lamellae

Glulam is increasingly being used in recent years and therefore more and more importance is being given to planing glued laminated timber lamellae. This depends on achieving a glueable surface at high speed with the lowest level of chip removal. Even the curve of the timber does not make a difference, and can be kept, because the lamellae are glued afterwards and then finally planed again.

WEINIG meets this challenge with innovative machine technology. The combination of slanted horizontal spindles and floating vertical spindles allows the lamellae to be planed with a minimum of chip removal on all four sides while maintaining the curvature of the wood. These WEINIG solutions increase material yield and thus also resource efficiency.

Window production

All stages of the processes on one machine

Profiling window scantlings on the long side and the cross side of the window scantling, and shaping and drilling are carried out on the processing center that outputs the fully processed scantling. However, the moulder still has an important role in window production as it is needed for 4-sided planing of the window scantling, to remove and to profile the blank glazing bead.

The WEINIG Powermat has a special window package that was precisely designed to complete these three process steps. Using the press of a button the user can select whether the four sides should only be planed or whether the blank glazing bead should be removed as well. Safety prompts ensure that an adjustment can only be carried out when there is no work piece in the machine and that there will be no collision between the saw blade and contact pressure elements. The PowerLock system means that the machine can be retooled in a very short time so that the glazing bead can be profiled.

The WEINIG system also enables the moulder to be connected to the cross-cut saw and the processing center. Thus, WEINIG offers the ideal solution for window production because it is the safest and most efficient.

Construction timber

The importance of solid wood as a construction material has grown constantly over the last few years. This means that there are high demands on the surface quality, particularly for the visible areas. The largest area of application are beams, which are planed on 4 sides and chamfered.

Depending on your requirements, WEINIG offers the right solution, from a small machine to a large line; but they have one thing in common: a high level of flexibility because of the 90° chamfering unit.

The chamfering unit is used to produce the fourth chamfer on the beam after the other chamfers have been produced by the vertical spindles and the horizontal top spindle. The chamfering unit control means that dimensions can be changed quickly and a change in the strength of the chamfer can be made without changing the tool and simply by positioning the spindles.

With this technology WEINIG enables small companies to work with the same economy as a large organization.

Pallet production

The Euro pallet has become an indispensable resource for transporting products and goods. As a result the production of pallets is an attractive market segment. However, pallet timber is not only planed on four sides but they also have chamfers that make it easier for the forklift to pick up the pallet. WEINIG offers a very efficient solution for pallet production, namely the jumping spindle that jumps in and out of a work piece. The basis for this is precise measurement, which allows the jumping spindle to be clocked at the right moment. The parameters of the chamfer, length and position on the work piece, can be defined by the machine operator.

The WEINIG solution with exact measurement and the dynamic spindle ensures that all chamfers have the same length are in the same position on the work piece. In addition, the “dip in” and “move-out” distances are equally long. In this way WEINIG meets all requirements for producing high-quality pallets in an economical way.

Profiled mouldings

Our core competence

Profiling mouldings of all types has always been WEINIG’s core competence. Profiling includes a wide range of end products that nevertheless set the same challenges for machine technology: high levels of profile precision with excellent surface quality and regular cuttermarks.

WEINIG technology is always setting new standards in this area. The basis for this are the solid machine bases with precise machine tables and the fence at exactly the right angle to this. The superiority of the WEINIG machines is seen overall when dynamics are brought into the equation: spindles with high true running accuracy, a strong feed system and the corresponding pressure elements.

The perfect interaction of these components guarantees smooth transportation in a defined position through the machine. The result is the legendary WEINIG quality of your products: high profile precision, excellent surface quality and regular cuttermarks.