WEINIG Conturex 124: The premium class all-rounder

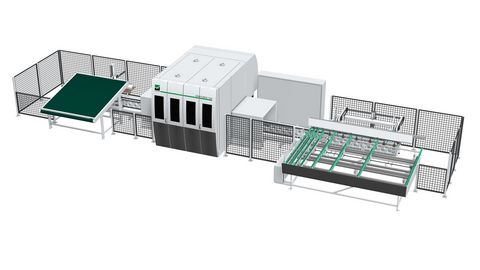

The Conturex 124 is equipped on the portal on both sides and offers space for four processing units. Unit configurations such as main spindle, 5-shaft head, uni-spindle, the WEINIG multi-spindle drill head or saw units meet every requirement in the mid-performance segment.

By using two main spindles, two profiler processes can be carried out on the work piece at the same time in one cycle. The Conturex 124 also has the same range of options as its colleagues 114 to 226. Mechanization systems for up to 3 hours of unstaffed production, measuring systems for veneered work pieces, scanners and laser projectors are only a part of the range of options.

The “multi-product capability” opens a host of possibilities. The unit can also efficiently manufacture products that are not related to windows and doors. Such as hinged shutters, casings and furniture and frame parts.

Different requirements - different prices

The price of a WEINIG machine is just as individual as your requirements are. Therefore, let us discuss briefly what is most important to you – you will then receive our preliminary, non-binding quote.

Personal advice – for higher productivity and greater efficiency

Together with your WEINIG expert you will find the ideal machine for your requirements. Simply submit the completed form, and your local WEINIG expert will be happy to discuss all further details with you.

The WEINIG Conturex series offers you

- Complete processing in one clamping process

- Processing without processing times even for small lot sizes

- Automation enables less manpower in production

- Maximum flexibility as a result of the large tool magazine

- Energy feedback modules means savings in energy

The WEINIG Conturex 124 offers you

- Low-vibration construction

- Advanced unit technology

- MBK – multiple spindle drilling head

- No limit to the corner joint possibilities

- Standard interfaces for industry software, e.g. window/door production, WOP or CAD/CAM software.

- High availability

Technical Details

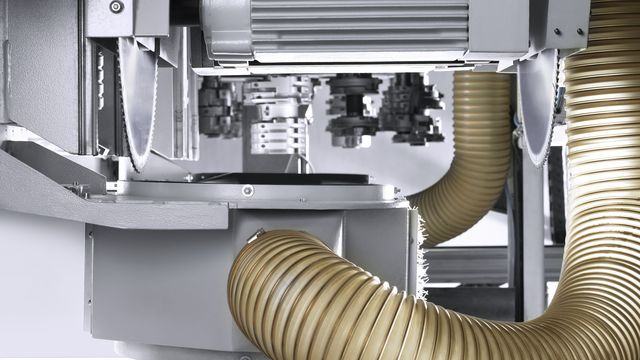

Safety – noise protection – dust protection

The visuals and design of the Conturex reflect the state-of-the-art technology inside it. The elaborate full paneling concept takes consistent account of the high performance. This yields an exemplary level of safety with improved protection from dust and noise.

The controlled extraction directly adjacent to the workpiece and on the tool is unique in the market. The machine functions without expensive chip removal and only requires minimum care.

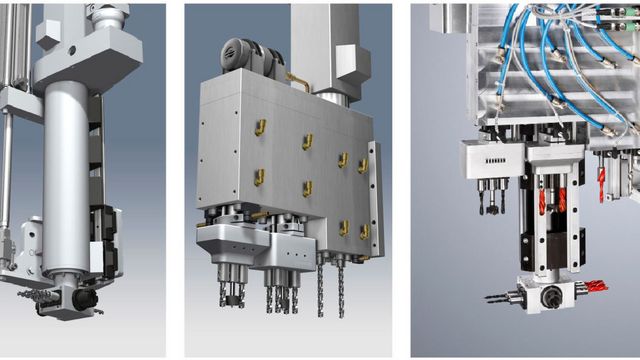

5-axis head (option)

- 5-axis head for maximum flexibility

- Includes 24-slot tool holder

Universal spindle with 5-axis technology (optional)

- 12.5 kW (S6)

- 6 kg tool weight

- Max. 220 mm tool length

- Includes 17-slot tool holder

Multiple spindle drilling head

The WEINIG multiple spindle drilling head covers such window production applications as door handles, corner bearings and horizontal drilling, such as corner joints and marking drillings. The device enhances the performance and flexibility of the individual Conturex models.

External tool magazine (optional)

The external tool magazine has up to 170 tools slots depending on the model range.

References

Further information

Brochures

Simple, fast and sustainable: more details in a downloadable PDF document.

WEINIG Conturex brochure (PDF, 1016 KB)