WEINIG HS 120 / HS 200: The nonplus ultra of the high-performance class

The horizontal single timber shapers from WEINIG are the fastest in the world. Continuous throughfeed of up to 200 parts per minute and 12 press cycles per minute make this system a production giant.

High-performance components such as fully-automatic feeding and front end control can also be integrated.

Wood that does not meet specific quality criteria can be excluded from further processing without being glued. Tool systems with varying diameters of 228.6 to 266.7 mm or 9 to 10 ½ inches can be run.

Different requirements - different prices

The price of a WEINIG machine is just as individual as your requirements are. Therefore, let us discuss briefly what is most important to you – you will then receive our preliminary, non-binding quote.

Personal advice – for higher productivity and greater efficiency

Together with your WEINIG expert you will find the ideal machine for your requirements. Simply submit the completed form, and your local WEINIG expert will be happy to discuss all further details with you.

WEINIG finger jointing line for short timber pieces offers you

- Finger joint profiles for all areas of use

- Maximum precision and stability of finger joints

- Robust and powerful

- High operational capacity, up to 200 pieces/min (28 km/8h-shiftr)

- Convenient and user-friendly

- Processing with one and two component glue

- Compact and efficient production process

- Statistics and production data recording

- Customized level of automation - from manual to fully automatic

- Expandable using peripheries, such as feeding systems and stacking systems

WEINIG HS 120/HS 200 offers you

- From a manual to a fully automatic system

- Heavy cast iron construction of the shaper body

- Shortest wood entry length 110 mm

- (Wood) quality monitoring, defective parts are automatically identified and removed

- Glue monitoring using a scanner (optional)

- Up to 200 parts/min (3.3 parts/s)

- Shaper spindles can be adjusted axially and radially

- Tool adjustment in the 1/100 mm range

- Motor pressure from above in the shaper range

- Inclusive teleservice (remote maintenance) for improved customer support

Technical Details

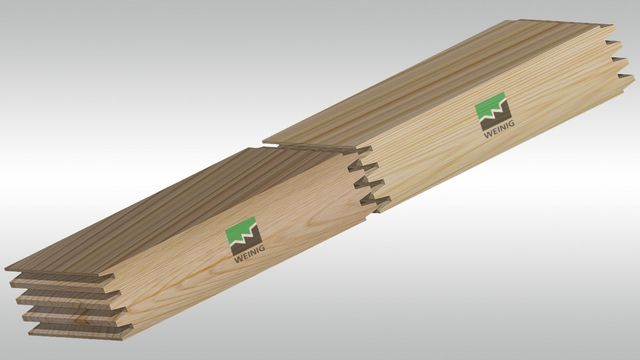

Horizontal finger joint

Horizontal finger joints are mainly used in furniture construction. The shoulder profiles provide, for example, table plates that look like parquet where only the straight butt joints are visible.

The positive-negative profile is the second most common profile in a shaper combination because the system only needs to be equipped with three scoring units instead of four and produces high quality visible joints.

The trapeze profile is also called “American Profile” because this finger joint originates from the US and is usually delivered with a finger joint length of 1/4 inch.

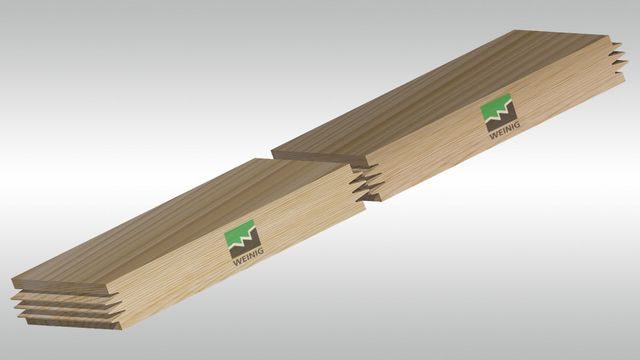

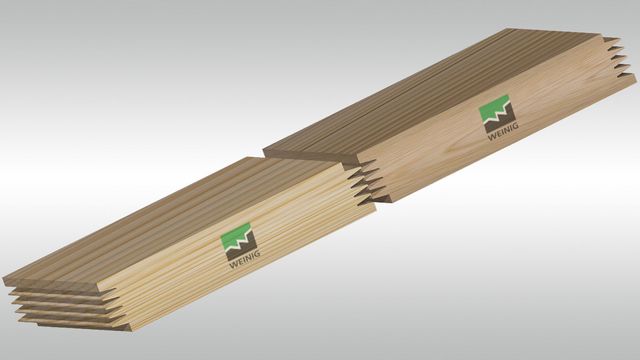

Horizontal finger joint (special)

Both of these horizontal profiles are special profiles and are hardly used in SOLID JOINT PS 2000 Combination because they only offer advantages with individual shaper lines.

The half shoulder profile can be run in manual and in fully automatic lines.

The reverse shoulder profile is mainly used for the simplest lines where, sometimes, no scoring unit is used.